Introduction: Mortise and Tenon Joint

- Open Slot Mortise And Tenon Joint Pain

- Angled Mortise And Tenon Joints

- Cutting Mortise And Tenon Joints

- Through Mortise And Tenon Joint

- Mortise And Tenon Machine

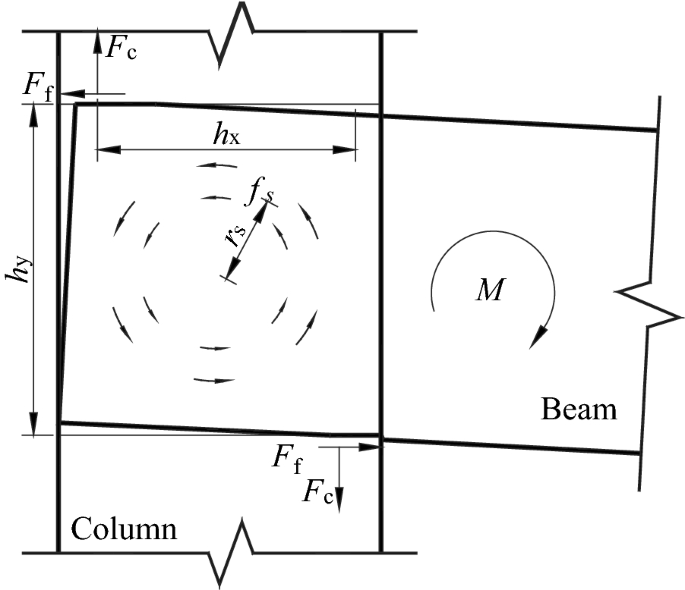

Mortise and tenon joint specimen The bamboo scrimber panels were processed into 10-mm-thick plates with aimed dimension. After the adhesive applied, the plates were inserted into the slots cut in the tenon. Then, the beam was cured in a chamber for 2 weeks with two steel clamps pressing the tenon and reinforcing plates tightly.

As part of another project I needed a door, I decided to make this myself. I decided perhaps rashly mortise & tenon joints would be in order.

Having never made one before I decided to do a practice one first I am not a regular wood worker, a few wood work lessons for one term back when I was 13 is all the instruction I've ever had, but I'm prepared to try my hand at pretty much anything. I've made this instructable in part to encourage others to have a go, and in part to get advice as to how I could have done it better from more experienced woodworkers.

please note a few of the photos are taken from the construction of the door, not my first actual attempt at doing this, even then they are only my next six joints.

Teacher Notes

Teachers! Did you use this instructable in your classroom?

Add a Teacher Note to share how you incorporated it into your lesson.

Step 1: Tools

I already had access to some good quality chisels, and a carpenters square.

Whilst I've cut halving joints and a fair few beams to size with a cheap hard point saw in the past I invested in a new cheap tenon saw, just £5 I liked the feel of this one the handle fitted my hand better than some more expensive budget ones, I also brought a cheap combination marking/ mortise gauge, this I could have done without but once set up it makes doing repeated joints much quicker. I also used a pencil, a Stanley knife,& Steel rule for marking out. A hand brace with a1/2' flat woodbit to remove the bulk of the wood from the mortise (I subsequently added a pad saw to my tools to save on chisel work).

My work bench was mostly an elderly folding work bench with clamping jaws salvaged from a skip more than 20 years ago.

Step 2: Set the Marking Gauge

measure the thicknesses of the timber devide by 3, set the fixed tang to 2/3 the thickness the moveable one to 1/3, lock and make a test mark on the timber swap sides check the points line up with the test mark adjust if needed.

Step 3: Marking Out

I laid my 2 pieces of wood in the T form and lightly marked the edges an end of the joint with the pencil.

I then positioned the carpenters square on these lines and marked them more firmly, I then checked theses lines were where I wanted them to be, happy they were I again used the square and pencil to mark around all 4 sides of each piece.

Hindsight 1) mark the orientation of the joint and use the marking gauge from the same side on each section unsurprisingly my set up wasn't as accurate as it should have been but matching the orientation means the error is in the same direction on both parts.

.

Once happy with the lay out in pencil I went over the lines again with a stanly knife still using the square for guidance. Now I remember we used marking knives at school the explanation was it made a cleaner cut than just the saw, I didn't used to bother with using a knife, but I noticed on occasions when I've not had a pencil to hand and just used a knife not only are my cuts cleaner they seem to be more accurate, I'm not sure if it needs more care to follow just a fine knife cut or if it some how guides the blade as it starts or if it is just an incorrect impression I've got

Step 4: Cut the Mortice

using a flat wood bit and a hand brace I chain drilled the mortise cavity taking care not to go all the way through to avoid splintering the exit side.I then drilled through from that side ( hindsight 2) this is probably what caused the ridge that stopped the joint closing those last 10 to 12mm see later step) I was able to trim the remaining webs out with a sharp knife I've taken to using a pad saw for this on followed up with a chisel.

The workmate tm (folding bench) is not substantial enough to stand the blows on the chisel so I worked on the ground with a scrap block under my work, hammering a chisel into the concrete won't do it any good, also keep your free hand behind the blade blood stains wood something terrible

Step 5: Cut the Tennon

Whilst it is perfectly possible to cut a tenon joint with any hand saw a proper hard backed tenon saw makes it easier, possibly in my opinion as a novice, a good hand grip is more important as good control of the cut is essential.

I started with the shoulders I cut carefully down to the edge of the tenon on both sides.

I then cut down the end grain along the faces of the tenon, this would have been easier with a vice that would hold the work vertical. I found I got best control by fixing my work horizontally in my work bench and sitting on top of it whilst making the initial cuts, once down to the shoulder of the tenon I turned the piece over and cut down to the shoulder of the tenon on the other side, once this was done it was possible to mount the piece vertically and cut squarely through the remaining triangular web of wood down to the shoulder, this was then repeated for the other side of the tenon

Step 6: Test and Trim

With the mortise and tenons cut it was time to do a trail fit.

The tenon would start in the mortician about 3mm(1/8') from either side so I pared a little off each face of the tenon with a chisel this allowed the joint to fit about a third of the way in, it was visible at this stage that my joint was off set and that the un-cut sections would not meet with a flush join it was also apparent that one way up the off set was less pronounced than the other.

At this point I marked the orientation of the joint something I should have done when marking out.

By removing wood only from the face of the tenon that was under flush with the mortise frame and later from that side of the mortise socket I was able to bring the joint together almost flush. After a little more wood being pared off the tenon from just the one face another fitting I noted the marks on the face of the tenon evidence of some tight spots in the mortise and cleaned up the inside of the mortise, this allowed the joint to almost close about 12mm short on a 63mm section.(on adding the photos I note part of the reason for this is I assembled the joint in the wrong orientation when I tapped (ok whacked it rather hard) it with a mallet

I thought that 'tap' with a mallet would close the joint and leave witness marks where the joint was still tight. Whist this was the case it also split the wood around the mortise .

Paring more wood off the face of the tenon and the inside of the mortise did result in a joint that closed reasonably flush and without opening up the split made by hammering the joint together.

Step 7: Next Step

Happy with my first attempt, I proceeded to make the frame for a simple two panel door.

The complete how to build a door may appear later as a stand alone instructable or as part of how I designed and built a shed.

Be the First to Share

Recommendations

Wearables Contest

Coffee Speed Challenge

Fix It Contest

A mortise (or mortice) and tenonjoint connects two pieces of wood or of other material. Woodworkers around the world have used it for thousands of years to join pieces of wood, mainly when the adjoining pieces connect at right angles.

In its most basic form, a mortise and tenon joint is both simple and strong. There are many variations of this type of joint, but the basic mortise and tenon comprises two components:

- the mortise hole, and

- the tenon tongue.

The tenon, formed on the end of a member generally referred to as a rail, fits into a square or rectangular hole cut into the other, corresponding member. The tenon is cut to fit the mortise hole exactly. It usually has shoulders that seat when the joint fully enters the mortise hole. The joint may be glued, pinned, or wedged to lock it in place.

This joint is also used with other materials. For example, it is traditionally used by both stonemasons and blacksmiths.

- 3Types

Etymology[edit]

The noun mortise, 'a hole or groove in which something is fitted to form a joint,' comes from c. 1400 from Old Frenchmortaise (13th c.), possibly from Arabicmurtazz, 'fastened,' past participle of razza, 'cut a mortise in.'[1]

The word tenon, a noun in English since the late 14th century, developed its sense of 'a projection inserted to make a joint' from the Old French tenir 'to hold.'[2]

History and ancient examples[edit]

Open Slot Mortise And Tenon Joint Pain

This is an ancient joint dating back 7,000 years. The first examples, tusked joints, were found in a well near Leipzig - the world's oldest intact wooden architecture.[3] It has also been found joining the wooden planks of the 'Khufu ship',[4] a 43.6 m long vessel sealed into a pit in the Giza pyramid complex of the Fourth Dynasty around 2500 BC. The oldest known use dates from the Early Neolithic Linear Pottery culture, where it was used in the constructing of the wooden lining of water wells.[5]

It has also been found in ancient furniture from archaeological sites in the Middle East, Europe and Asia. Many instances are found, for example, in ruins of houses in the Silk Road kingdom of Cadota, dating from the first to the fourth century BC.[6] In traditional Chinese architecture, wood components, such as beams, brackets, roof frames and struts, were made to interlock with perfect fit, without using fasteners or glues, enabling the wood to expand and contract according to humidity.[7] Archaeological evidence from Chinese sites shows that, by the end of the Neolithic, mortise-and-tenon joinery was employed in Chinese construction.[8]

The thirty sarsen stones of Stonehenge were dressed and fashioned with mortise-and-tenon joints before they were erected between 2600 and 2400 BC. English Heritage - Building Stonehenge

Types[edit]

Mortises[edit]

A mortise is a cavity cut into a timber to receive a tenon. There are several kinds of mortise:[9]

- Open mortise

- a mortise that has only three sides. (See bridle joint).

- Stub mortise

- a shallow mortise, the depth of which depends on the size of the timber; also a mortise that does not go through the workpiece (as opposed to a 'through mortise').

- Through mortise

- a mortise that passes entirely through a piece.

- Wedged half-dovetail

- a mortise in which the back is wider, or taller, than the front, or opening. The space for the wedge initially leaves room to insert the tenon. The wedge, after the tenon is engaged, prevents its withdrawal.

- Through-wedged half-dovetail

- a wedged half-dovetail mortise that passes entirely through the piece.

Tenons[edit]

Angled Mortise And Tenon Joints

A tenon is a projection on the end of a timber for insertion into a mortise. Usually the tenon is taller than it is wide. There are several kinds of tenon:

- Stub tenon

- short, the depth of which depends on the size of the timber; also a tenon that is shorter than the width of the mortised piece so the tenon does not show (as opposed to a 'through tenon').

- Through tenon

- a tenon that passes entirely through the piece of wood it is inserted into, being clearly visible on the back side.

- Loose tenon

- a tenon that is a separate part of the joint, as opposed to a fixed tenon that is an integral part of one of the pieces to be joined.

- Biscuit tenon

- a thin oval piece of wood, shaped like a biscuit[10]

- Pegged (or pinned) tenon

- the joint is strengthened by driving a peg or dowel pin (treenail) through one or more holes drilled through mortise side wall and tenon;[11] this is common in timber framing joints

- Tusk tenon

- a kind of mortise and tenon joint that uses a wedge-shaped key to hold the joint together.

- Teasel (or teazle) tenon

- a term used for the tenon on top of a jowled or gunstock post, which is typically received by the mortise in the underside of a tie beam. A common element of the English tying joint.

- Top tenon

- the tenon that occurs on top of a post.

- Hammer-headed tenon

- a method of forming a tenon joint when the shoulders cannot be tightened with a clamp.

- Half shoulder tenon

- An asymmetric tenon with a shoulder on one side only. A common use is in framed, ledged and braced doors.

Further details about the completed joint[edit]

Generally, the size of the mortise and tenon is related to the thickness of the timbers. It is good practice to proportion the tenon as one third the thickness of the rail, or as close to this as is practical. The haunch, the cut-away part of a sash corner joint that prevents the tenon coming loose, is one third the length of the tenon and one sixth of the width of the tenon in its depth. The remaining two-thirds of the rail, the tenon shoulders, help to counteract lateral forces that might tweak the tenon from the mortise, contributing to its strength. These also serve to hide imperfections in the opening of the mortise.

Gallery of various mortises[edit]

Cutting Mortise And Tenon Joints

A traditional through, wedged, mortise and tenon joint

A stub tenon corner joint

A haunched stub tenon corner joint

A foxtail wedged tenon joint

A pinned corner tenon joint

A modern feather tenon joint (primarily called a loose tenon)

See also[edit]

Through Mortise And Tenon Joint

References[edit]

Mortise And Tenon Machine

- ^Harper, Douglas. 'mortise'. Online Etymology Dictionary. Retrieved 2019-02-19.

- ^Harper, Douglas. 'tenon'. Online Etymology Dictionary. Retrieved 2019-02-19.

- ^'The Neolithic Toolkit'. Archaeology.org. Retrieved 7 January 2015.

- ^Ward, Cheryl. 'World's Oldest Planked Boats,' in Archaeology (Volume 54, Number 3, May/June 2001). Archaeological Institute of America.

- ^Early Neolithic Water Wells Reveal the World's Oldest Wood Architecture Tegel W, Elburg R, Hakelberg D, Stäuble H, Büntgen U (2012) Early Neolithic Water Wells Reveal the World's Oldest Wood Architecture. PLoS ONE 7(12): e51374. doi:10.1371/journal.pone.0051374

- ^Roberts, Rachel (2012). 'House-building in Ancient Niya'. IDP News. 39. Retrieved 26 October 2012.

- ^Steinhardt, Nancy W. (2002). Chinese Architecture (English ed.). Yale University Press. p. 1. ISBN978-0-300-09559-3.

- ^Xujie, Liu (2002). Chinese Architecture - The Origins of Chinese Architecture (English ed.). Yale University Press. p. 11. ISBN978-0-300-09559-3.

- ^Dekker, Michael. 'Mortise-and-Tenon'. Woodwork Details. Retrieved 2015-02-18.

- ^'Our Reviews, Your Decision'. Man Of Family. Retrieved 2017-07-28.

- ^Teague, Matthew (May 2007). 'The Pegged Joint, Exposed'. Fine Woodworking. Taunton Press. Retrieved 2015-02-18.

- This article is partly based on a Quicksilver wiki article at A Glossary of Terms For Traditional Timber Framing (Timberbee) under the terms of the GNU Free Documentation License.